Everything about amino acid and the process of making it

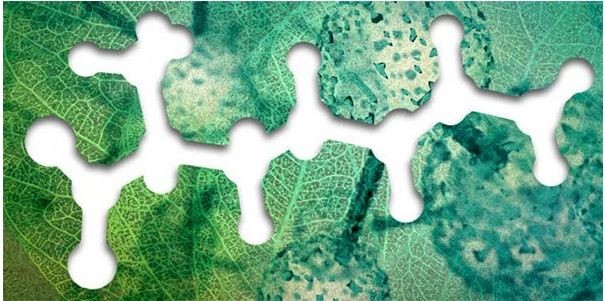

One of the most important factors for better plant growth is the quality of their fertilizer. As you know, amino acids are one of the mineral substances present in fertilizers that have a significant impact on plant growth. Therefore, in this text, we want to talk about how to hydrolyze protein waste to produce amino acids in agricultural fertilizers.

The hydrolysis of protein waste for making amino acid fertilizers mostly has three different steps: pre-treatment for raw materials, protein hydrolysis, and producing the aminofertilizer.

Raw material and pretreatment

Raw material resources: these materials actually are wastes from treated amino acids. Such as: animal waste. Also, vegetable oils fulfill protein like leather, hair, nail, blood, cotton waste and beans.

Protein hydrolysis

There is lots of research about producing amino acids from protein hydrolysis. The main methods of protein hydrolysis are: acid hydrolysis, ultrasound, microwave and…

The amino acids produced with acidic hydrolysis mostly have a high acidity. There are two methods for reducing and eliminating the acid.Neutralization and evaporation. The neutralization method removes the acid in hydrolysis by acid-base neutralization. At the same time, it forms a special salt. The materials that are usually used for neutralization of acid are alkali metal salts such as sodium hydroxide, potassium hydroxide, and calcium hydroxide. Ammonia and ammonium salts are neutral. So, it will depend on the product and economic costs. This method can be used for all acid hydrolysis solutions.

Evaporation under reduced pressure

Acid will be removed and recycled by evaporation under reduced pressure. This method can be used for producing amino acids with protein hydrolysis. But it needs lots of energy and it’s not useful for removing the acid. Somehow It is only used in experimental research. Producing amino acid in big amounts mostly is done with ammonia neutralization and drying sprays.

The base used for alkaline hydrolysis is sodium hydroxide and potassium hydroxide. Most amino acids will be removed in different grades of hydrolysis process. They create a racemized (inactive) compound and the rate of hydrolysis is usually lower than acid hydrolysis. Amino acid hydrolysates prepared by alkaline hydrolysis usually contain a large amount of a base that must be neutralized. We can neutralize them with acid hydrolysis or protein acids.

Enzymatic hydrolysis

Enzymatic hydrolysis will not produce race composition and cannot remove proteins. However, an enzyme cannot hydrolyze a protein completely, and usually we need to merge several enzymes for complete hydrolyzation of the protein.

We can use enzymatic hydrolysis directly with enzymes. Also, we can do this method with microbial fermentation. Proteins produced by microorganisms can be used to hydrolyze proteins into amino acids.

Enzymatic hydrolysis conditions are relatively hard, and the technology for microbial fermentation is not functional enough for producing amino acids in large quantities. Since enzymatic hydrolysis does not require a neutralization method, fertilizer will not be infected with a neutralizer. In production by enzymatic hydrolysis, there are no adverse effects of salt accumulation caused by continuous cultivation in the ground.

Conclusion

Ultimately, we must say that there are many solutions for the hydrolysis of proteins to produce amino acids and use them in agricultural industries. Nowadays, many companies are active in this field, and based on the demand, budget, and preferences of the applicants, they are taking steps to use these new methods.

No comment